Value Stream Mapping

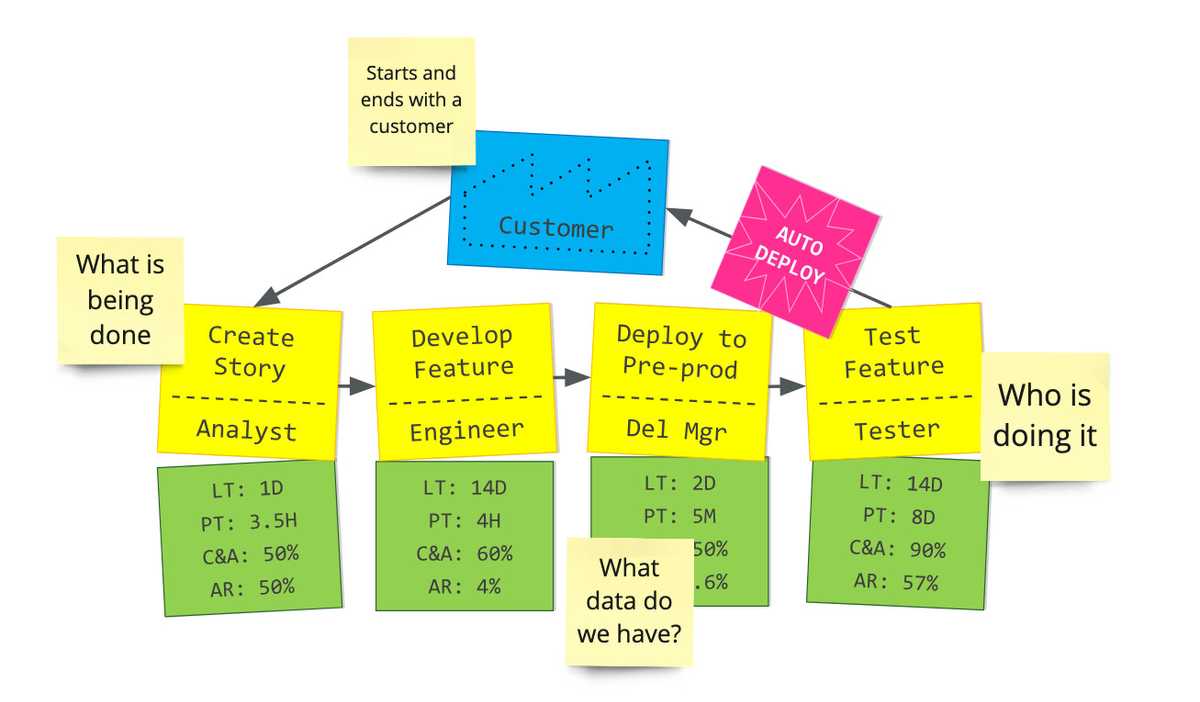

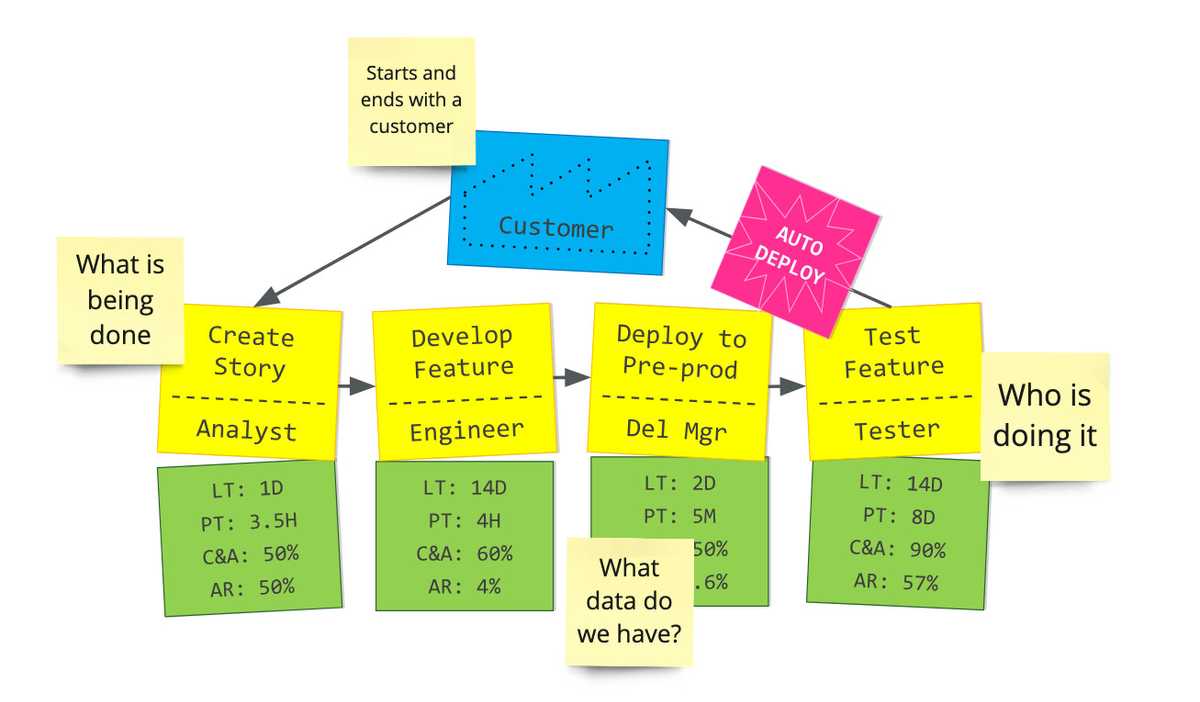

- Select the Process: Identify and define the specific process or product line to be mapped, ensuring it has a clear start and end point.

- Gather Data: Collect detailed information on lead time, process time, and complete and accurate for each step of the process.

- Create Current State Map: Use diagrams to visually represent the current process flow, including all steps, delays, and information flows.

- Analyze the Current State: Examine the map to identify areas of waste, such as excess inventory, waiting times, and unnecessary movements or processes.

- Design Future State Map: Develop a new map that eliminates identified wastes and inefficiencies, streamlines steps, and optimizes the flow of materials and information.

- Implement Changes: Put the new process design into practice, train staff on the changes, and establish metrics to monitor the effectiveness of the improvements.